UW-Madison Researchers Use 3D Printing Technology to Develop More Efficient Electric Motor

by Sedona Afeworki, age 15

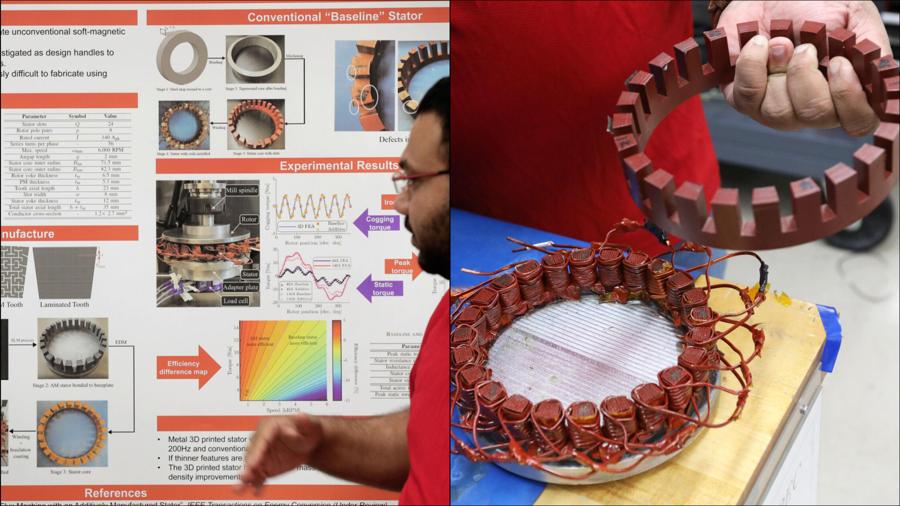

Four researchers from UW-Madison have achieved a groundbreaking feat by developing an electric motor using 3D printing technology. According to The Wisconsin State Journal, this prototype incorporates a "higher-percentage silicon electrical steel," which effectively reduces energy loss.

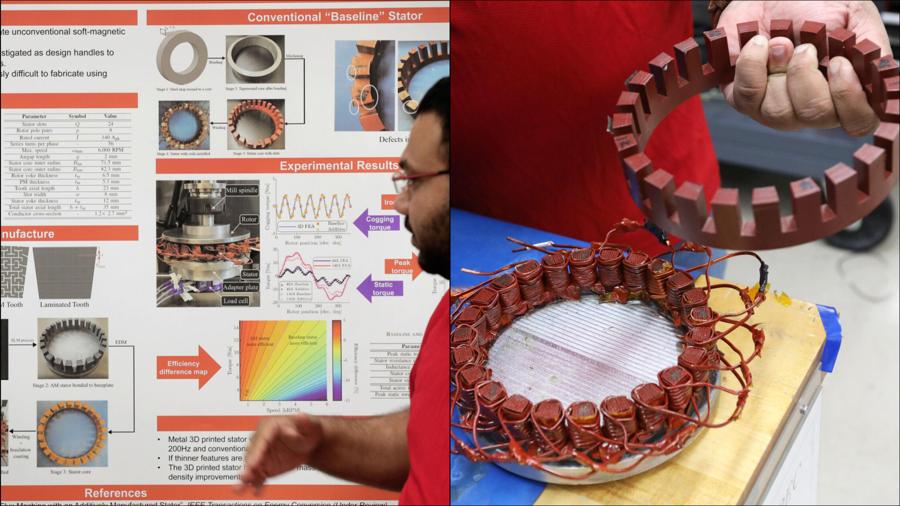

The prototype takes on a circular shape with prongs designed for winding wires around them, allowing for the generation of an electrical field, also known as a stator. The most significant innovation in the design lies in the prongs themselves, featuring intricate patterns of thin geometric lines aimed at minimizing energy loss. In contrast, the conventional method for producing such stators involves a lamination process that rolls coils of electrical steel.

The team responsible for creating this motor prototype hails from both UW-Madison and England. It comprises FNU Nishanth, a post-doctoral research assistant at UW-Madison, and his advisor, Eric Severson, along with Alexander Goodall, a Ph.D. student at the University of Sheffield in England, and his advisor, Iain Todd. The collaborative effort began in July 2020 when they met at a conference and recognized the potential to jointly develop an entirely new type of motor.

By October 2022, they had a printed prototype ready for testing. At that point, there were doubts about its functionality, but Nishanth conducted tests in his Engineering Hall lab. After applying an electric current and rerunning the tests, he discovered that the motor was generating more energy than expected, despite using less material.

Nishanth stated, "When you have 30% lower mass, you would expect that your torque would also get lower… but that wasn't the case. So, this shows that you're going to net torque density improvement in this machine, and if we can further improve this, it would be a game changer."

This development is yet another example of meeting the current high demand for more efficient electric motors.

[Sources: Wisconsin State Journal; Madison.com; UW-Madison]

Loading Comments...